- Products

- JNCTION Control

Reduce delays and improve network performance

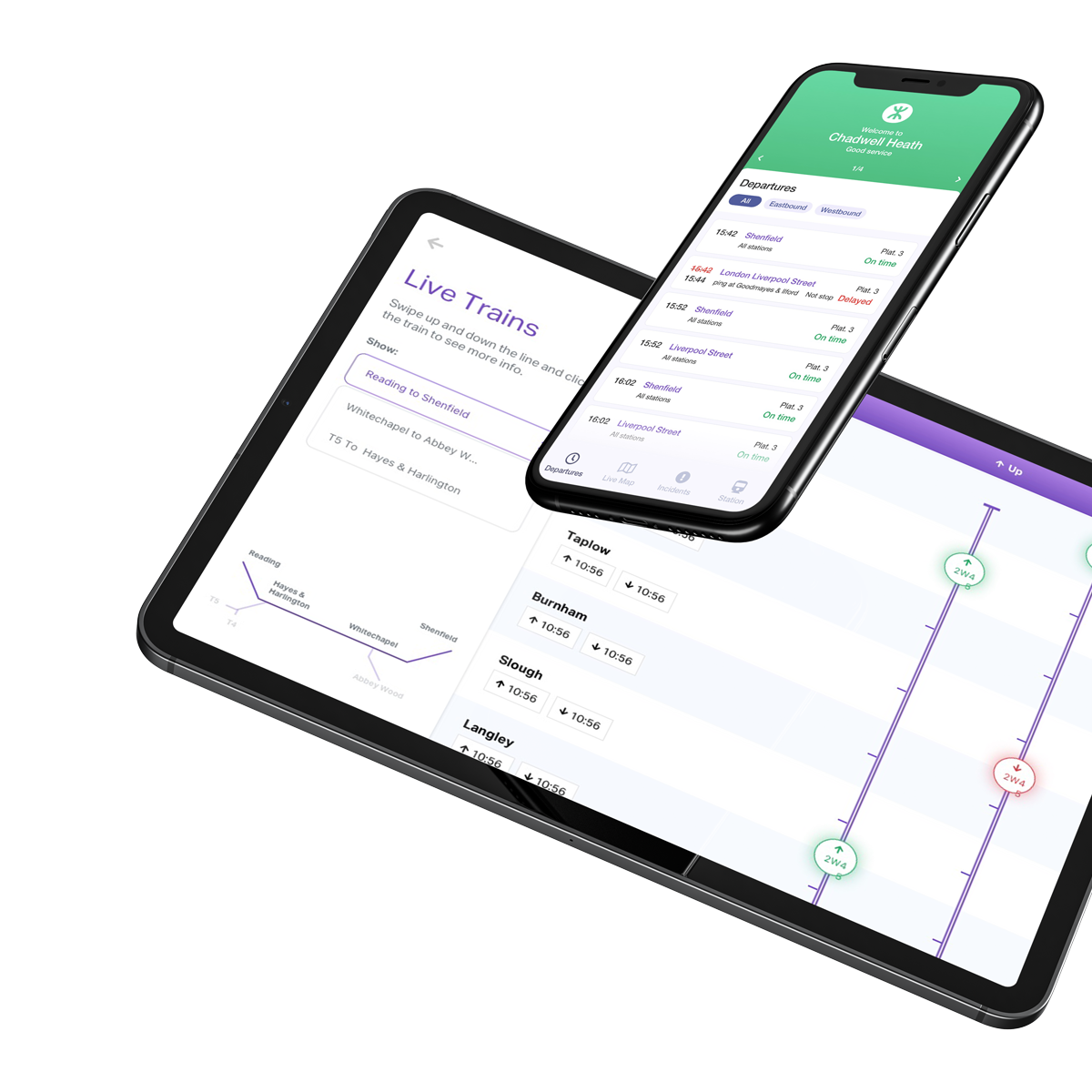

- JNCTION Frontline

Deliver real-time station information to passengers

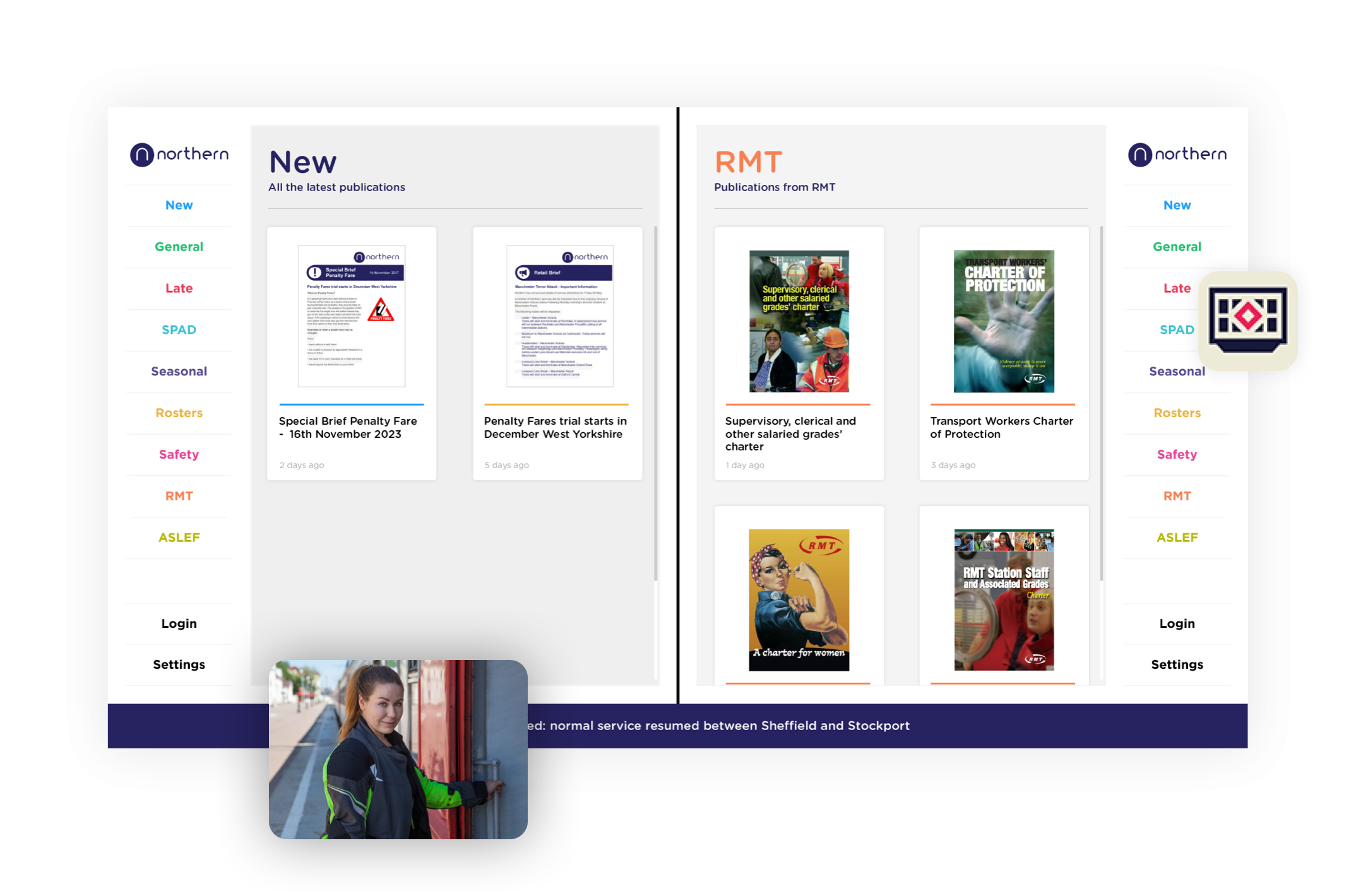

- JNCTION Notice Board

Streamlining communication and enhancing efficiency

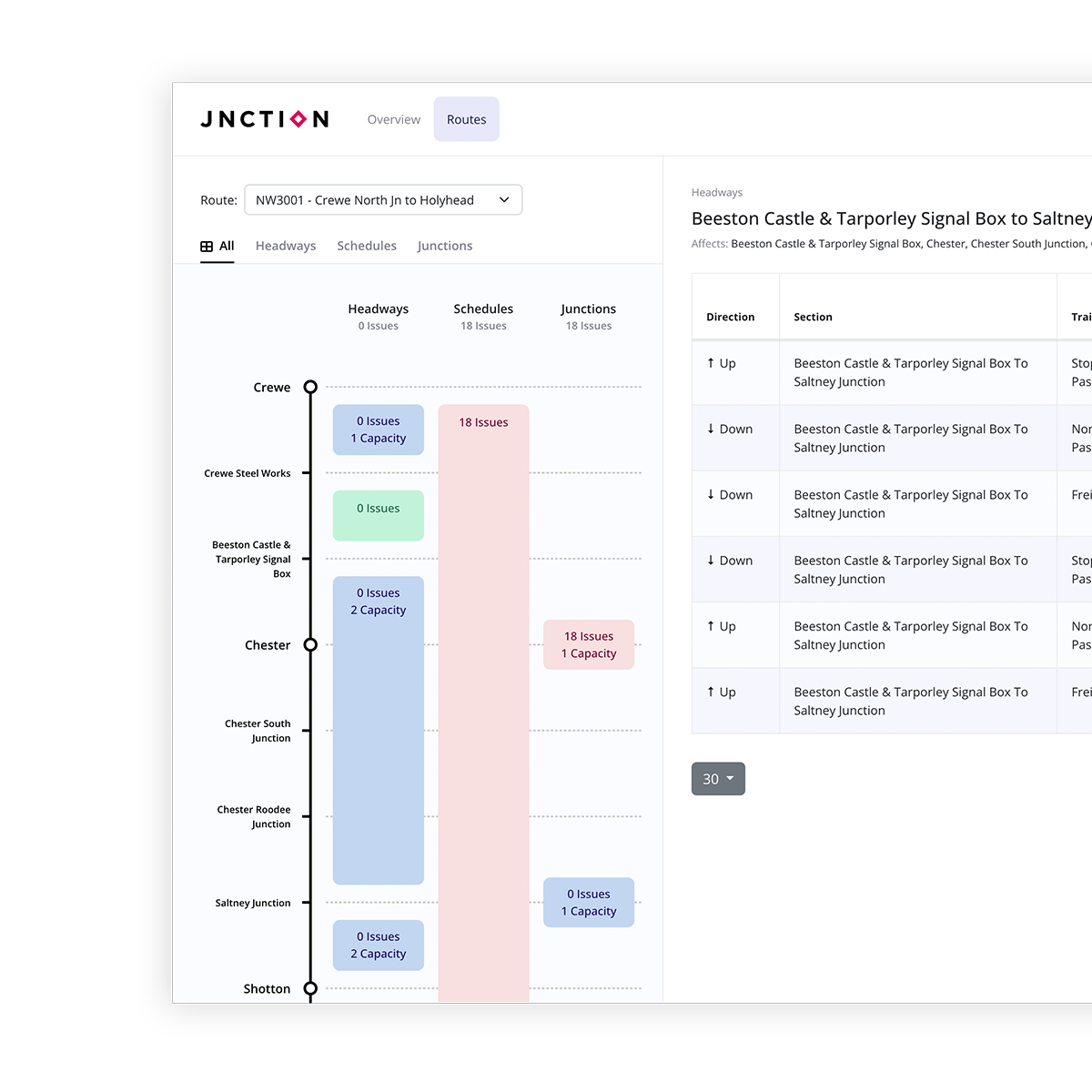

- JNCTION Analyse

Analyse train movements and timetable planning rules

- JNCTION LiveData

Real-time train movement data engine

- JNCTION Archive

Download historic train movements data for use in software or analysis

- Services

- Products

- JNCTION Notice Board

Centralised notice management

Boost efficiency, accuracy, and security with real-time updates.

Train depot challenges

Train depots face several challenges with managing paper driver notices, including the time-consuming and error-prone process of printing and posting updates, leading to potential delays and inaccuracies in communication.

Accessibility issues arise as drivers may not consistently check noticeboards, and space constraints can result in critical information being overlooked. Environmental concerns, ongoing costs for materials, and the physical wear and tear of notices further complicate this system. Additionally, tracking driver compliance is difficult, and sensitive information may be exposed on public boards, raising security and confidentiality issues. These factors underscore the inefficiencies and risks associated with relying on paper-based notices.

The Digital Notice Board addresses these challenges by:

Automated updates

Instant, real-time updates ensure that all information is current and accurate, reducing the risk of outdated notices.

Centralised management

A centralised system for creating, updating, and distributing notices minimises human error and streamlines the process.

Accessibility

The digital notice board can be accessed remotely via mobile devices or computers, ensuring drivers can view important information anytime and anywhere.

Compliance tracking

The digital notice board can track which drivers have read and acknowledged each notice, ensuring compliance and enhancing safety protocols.

Security and confidentiality

The digital notice boards can restrict access to sensitive information, ensuring that only authorised personnel can view certain notices.

Notifications and alerts

Automated alerts and notifications can remind drivers to check new updates, ensuring that they are always informed of the latest information.

Cost Implications

Continuous printing and the need for physical materials (paper, ink, printers, etc.) incur ongoing costs. Over time, these expenses can add up, straining the depot’s budget.

Physical Wear and Tear

Notices can get damaged, torn, or removed from the board, especially in high-traffic areas. This can result in important information not being available when needed.

Benefits of the Digital Notice Board for Train Depots

Improved Efficiency

Real-time updates and centralised management streamline the process of disseminating information, saving time and reducing administrative burden.

Enhanced Accuracy

Automation reduces the risk of human error associated with manual processes, ensuring that information is consistently accurate and up-to-date.

Environmental Sustainability

By reducing paper usage and promoting digital communication, train depots can contribute to environmental conservation efforts and reduce their carbon footprint.

Enhanced Security

Digital systems can implement access controls and encryption to protect sensitive information, ensuring confidentiality and compliance with privacy regulations.

Increased Awareness

Automated notifications and alerts remind drivers to check for updates regularly, reducing the risk of critical information being overlooked or missed.

Long-Term Durability

Digital notice boards are not subject to physical wear and tear, ensuring that information remains intact and accessible over time.

Bespoke Rail Solutions

We understand that one size doesn’t fit all when it comes to rail. That’s why we offer bespoke services and customisable modules which can be mix-and-matched to ensure that your rail solutions perfectly align with your unique requirements.

We pride ourselves on our flexibility and agility, seamlessly integrating custom solutions into your project timeline and budget.

Whether you’re looking to enhance safety, improve efficiency, or optimise performance, we ensure that your railway system is tailored to meet your exact requirements.

For a consultation or a product demo, please get in touch.

Or alternatively, call us on 0203 011 1008

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.Manage consent

We use cookies on our website to give you the most relevant experience by remembering your preferences and repeat visits. By clicking “Accept”, you consent to the use of ALL the cookies.Manage consentPrivacy Overview

This website uses cookies to improve your experience while you navigate through the website. Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. We also use third-party cookies that help us analyze and understand how you use this website. These cookies will be stored in your browser only with your consent. You also have the option to opt-out of these cookies. But opting out of some of these cookies may affect your browsing experience.Necessary cookies are absolutely essential for the website to function properly. These cookies ensure basic functionalities and security features of the website, anonymously.Cookie Duration Description cookielawinfo-checbox-analytics 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". cookielawinfo-checbox-functional 11 months The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". cookielawinfo-checbox-others 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. cookielawinfo-checkbox-necessary 11 months This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". cookielawinfo-checkbox-performance 11 months This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". viewed_cookie_policy 11 months The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. Functional cookies help to perform certain functionalities like sharing the content of the website on social media platforms, collect feedbacks, and other third-party features.Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors.Analytical cookies are used to understand how visitors interact with the website. These cookies help provide information on metrics the number of visitors, bounce rate, traffic source, etc.Advertisement cookies are used to provide visitors with relevant ads and marketing campaigns. These cookies track visitors across websites and collect information to provide customized ads.Other uncategorized cookies are those that are being analyzed and have not been classified into a category as yet. - JNCTION Control